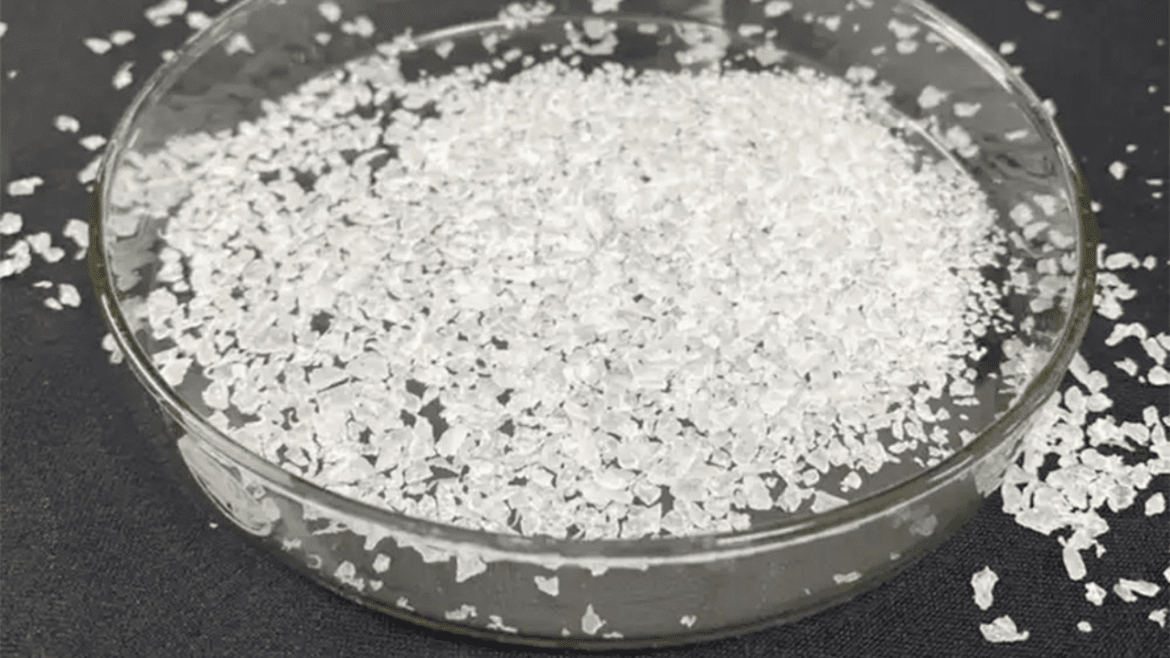

Polyvinyl Alcohol 2488 is a top-tier polymer for multiple industry uses. It is helpful for many industries because it creates strong, durable films that stretch easily while staying see-through. This research examines how PVA 2488 creates films and why manufacturers use it across industries.

Understand How Films Form in Industrial Situations

Essential production steps depend on making films through coatings, adhesives, and packaging materials. Materials that create thin films need balanced strength, flexibility, and transparency to work well in their target applications. PVA 2488 stands out because it produces films delivering all necessary properties simultaneously.

When a polymer material is spread onto a surface, its self-organizing properties naturally create a thin covering. Films from these materials must balance strength with flexibility to withstand pressure under clear conditions, mainly when used for surface coatings and packaging. The pva 2488 wholesale delivers perfect performance by meeting every film-forming requirement for industrial applications.

PVA 2488: The Perfect Polymer for Film Formation

PVA 2488 is a superior Polyvinyl Alcohol variant due to its remarkable capability to create transparent films. Its water solubility and film strength make it an excellent option for film production. The material delivers fantastic results for film-based applications across packaging, adhesive, coating, and textile sectors.

PVA 2488 separates itself from other film-forming agents through its distinctive molecular design and dissolvability profile. PVA 2488 stands out from other polymers because its simple water-dissolving method provides flexibility across many product formulations. Thanks to its simple solubility and wide adaptability, PVA 2488 works well for many industries to create coatings, glues, paints, and other surface materials.

Strength: Enhancing Durability and Performance

PVA 2488 stands out because it offers strong resistance to tension. Its films create a firm bonding surface that withstands stress and shearing forces. Because of its exceptional strength properties, the polymer performs well in challenging applications that demand durability.

Industrial manufacturers rely on PVA 2488 film strength to keep their products functional through harsh operating conditions. The polymer’s bond strength enables it to create practical attachments between multiple substrates, especially paper, wood, and fabric, through strong adhesives.

Flexibility: Enabling Versatile Applications

Building projects benefit from PVA 2488’s unique ability to adapt to different situations. The polymer remains structurally strong and works well across different applications thanks to its stretchability. The material works exceptionally well in coating applications and adhesives because it stays flexible without losing its strength benefits.

PVA 2488 works best in flexible packaging and paper coating industries because it stays firm under pressure. Manufacturers use its flexibility to produce synthetic materials, which have become usable for clothing and industrial components.

Transparency: Optical Clarity and Industrial Use Cases

How well you can see through PVA 2488 is essential in product applications that depend on visual appearance. Industry packagers turn PVA 2488 into explicit films that protect products while showing their contents. The transparent nature of PVA 2488 films lets users see packaging and coatings clearly while preserving their attractive visual appeal and working function.

PVA 2488 stands out as the most effective transparent polymer because it possesses superior clarity and durability, which benefits industries focused on optical solutions. This material also makes strong transparent coatings and protective films resistant to physical harm and environmental threats.

Environmental and Sustainability Aspects

Sustainability has become a vital factor in how modern industries produce goods. PVA 2488 delivers sustainable features through its organic decomposition. The material can be safely used because it naturally breaks down and does not harm the environment or waste disposal infrastructure. We recommend this material because it helps companies reduce their environmental impact without losing industrial production effectiveness.

PVA 2488 can safely break down and support today’s environmental regulations. Using biodegradable PVA 2488 meets performance and production needs while allowing industries to adjust their operations to sustainability rules.

Conclusion

PVA 2488 is a strong and adaptable material for creating films that stay transparent and bend without breaking. It performs excellently in multiple industries because its distinct molecular design enables it to dissolve easily across different applications. Companies choose PVA 2488 films because their strong and flexible membranes deliver top performance and lasting durability in their products.

Thanks to its ideal performance characteristics, PVA 2488 works perfectly with products from packaging and coating to textile manufacturing. Today’s market demands environmentally conscious products, and PVA 2488 meets this need by breaking it down quickly. PVA 2488 will keep growing as a popular material for film applications because it delivers exceptional performance and helps protect the environment.