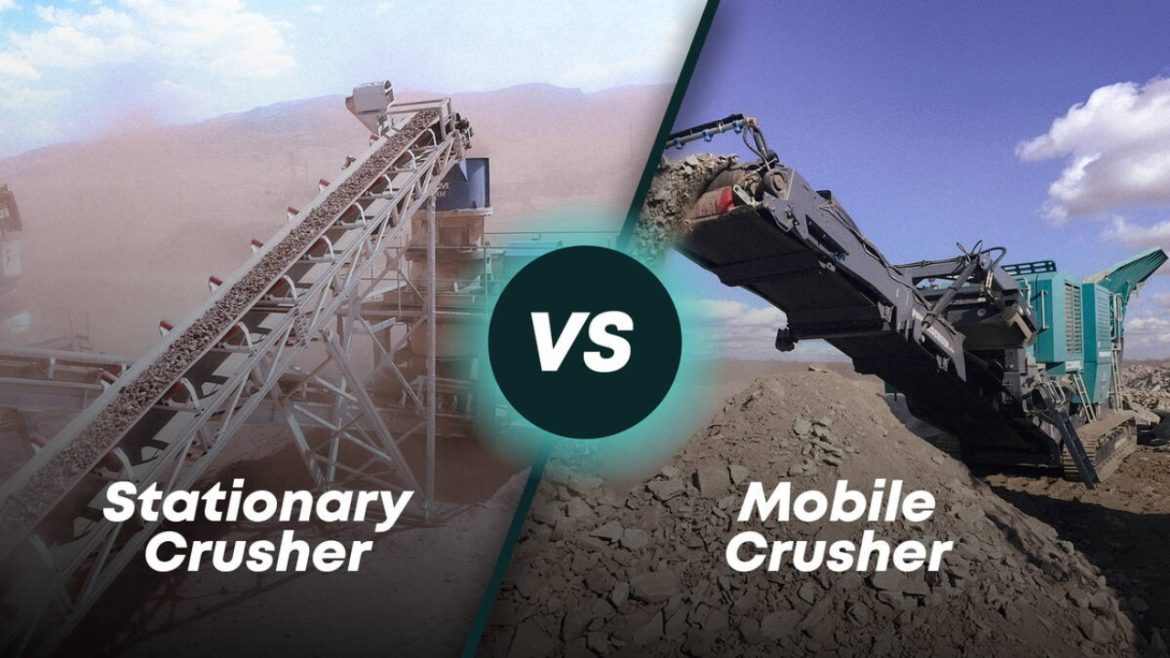

Rock processing requires rock crushers for mining, construction projects, and more. Crushers play a vital role by processing large stones into usable aggregates for everyday applications. The processing industries work with two primary crushing types: portable equipment and stationary installations. Your crusher selection depends on its intended purpose and specific crushing requirements. Just keep reading to find out enticing facts!

Understanding Portable Crushers

Portable crushers feature a mobile design for effortless movement from one work location to another. They run on-site using their built-in crushing features and strong engine power without needing extensive support systems. These machines come as either track or wheel platforms with unique advantages for each version.

Today’s manufacturers employ four basic crusher types: jaw crushers, impact crushers, cone crushers, and sand-making equipment. Our portable jaw crusher system handles materials below 750mm and produces output volumes between 20 and 450 tons per hour. Portable impact crushers deliver reliable performance on materials less than 300mm, while portable cone crushers handle stiff mid-hard materials and generate 50 to 300 tons of product per hour. A moveable sand-making machine creates suitable aggregates for projects requiring fine materials.

The portable crusher offers significant benefits because it can move quickly. Its ability to move between different job sites quickly makes it ideal for short-term activities and remote work. It can also rapidly deploy and adjust to various ground conditions for many projects.

Understanding Stationary Crushers

Stationary crushers remain in place as permanent equipment for large mines or facilities. These machines deliver high-volume processing by handling large amounts of material without interruption. Stationary crushers perform heavy-duty operations while being bigger and stronger than portable versions.

Since stationary crushers remain fixed at one location, they can deliver sustained optimal output. Their advanced processing power and continuous workability match mining sites and aggregate facilities that function smoothly.

Portable and Stationary Crushers Work Differently in Important Ways

The main difference between portable and stationary crushers lies in how they move. Portable crushers come ready to move between projects, while stationary crushers stay put at a single installation. Portable crushers work best when projects must move from one location to another.

Stationary crushers deliver more material output compared to portable crushers. These units operate permanently at one location to process large amounts of materials effectively in mining and aggregate production settings.

Portable crushers adapt by moving between different project locations while maintaining scale. Stationary crushers work best when focused on one material type but lack the versatility of portable crushers.

Although portable crushers offer initial savings, consumers typically achieve better long-term investment value through stationary crushers. Although stationary units demand more capital upfront, they generate lower running expenses thanks to their long service life and ability to process heavy loads without frequent breakdowns.

Performance Comparison: Efficiency, Energy, and Maintenance

Stationary crushers deliver steady results throughout their service life by maintaining high production levels. The efficiency output of portable crushers varies with changes in site conditions and how often they run.

Thanks to their electric and hybrid engine models, portable crushers use less energy than stationary crushers. Their portable design lets them operate without needing much infrastructure or energy supply.

Stationary crushers maintain easier upkeep because they remain stable in the same spot. The large size of these machines creates long repair downtime periods. Regular maintenance on portable crushers increases when operating in multiple locations.

Best Use Cases for Portable and Stationary Crushers

Portable crushers serve effective roles for temporary duties or projects that need transportation flexibility. Portable crushers work best when teams need them at construction sites, building remote locations, or recycling facilities. You can move portable crushers from one place to another, making them perfect for handling temporary work requirements.

Stationary crushers handle large material flows without interruptions in steady production settings. Placing a crusher at a fixed location becomes more profitable when mining areas regularly need to handle substantial material volumes.

Conclusion

Your decision between portable and stationary crushers depends on criteria such as project timeline materials type, material processing volume, and machine output capacity. Crushers’ portability lets them handle short-term projects and reach distant locations easily. Stationary crushers produce more material while needing less upkeep and operate best for large-scale processing systems.

Your decision depends on your project’s unique demands. A portable crusher is your best option if you need equipment that moves quickly between projects. A stationary crusher is necessary for consistent production work on permanent facilities. Look at your project details and financial needs to choose wisely.