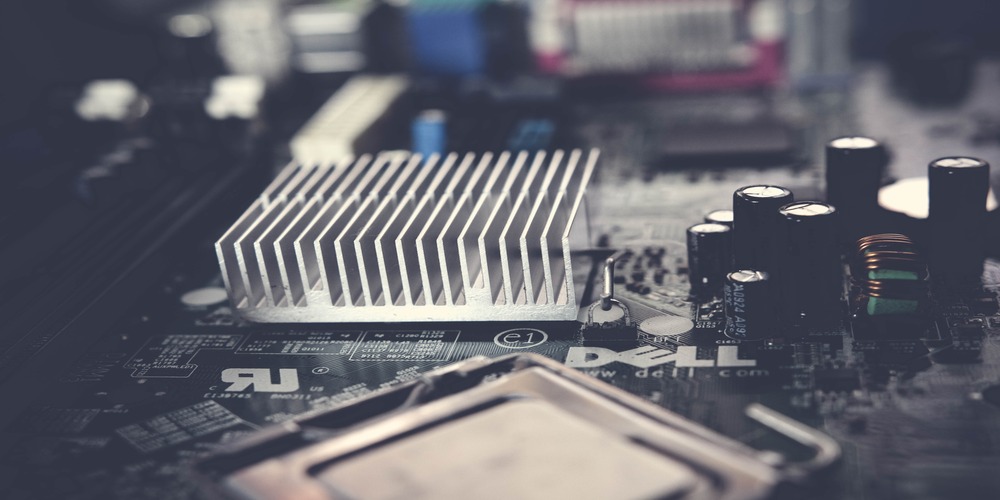

When it comes to heavy machinery and industrial equipment, heat can be a major enemy. Overheating can cause equipment malfunction, damage, and even safety hazards. This is where heat sinks come into play.

Heat sinks are nifty devices that help dissipate heat away from electronic components, allowing them to operate at a safe temperature. Choosing the right heat sink can be daunting, but with the right knowledge, you can make an informed decision.

In this article, we’ll provide a comprehensive guide to selecting the right heat sink for your needs.

Understanding Heat Sinks

In the world of heavy industrial machinery, heat sinks are essential components for efficient thermal management. These devices draw heat away from critical components, such as motors, transformers, and power supplies, and dissipate it into the surrounding environment.

This helps prevent overheating and ensures optimal performance and longevity of the equipment. They come in different shapes and sizes, and choosing the right one depends on various factors, such as the heat load, the airflow available, and the mounting options.

Key Factors to Consider When Selecting a Heat Sink

When it comes to selecting the right heat sink for your needs, there are a few key factors that you should take into account. These factors can vary depending on the application and the specific requirements.

For example, if you’re looking for a heat sink for soldering then there are some specific considerations to remember. Here are the key factors to consider when selecting a heat sink:

Thermal Performance

This is the primary consideration when selecting a heat sink. The heat sink’s thermal performance is determined by its ability to dissipate heat from the device it is attached to. The higher the thermal performance, the better the heat sink.

Size and Weight

The size and weight of the heat sink will depend on the size and weight of the device it is attached to. The heat sink should be large enough to dissipate heat effectively but not so large that it adds unnecessary weight to the device.

Materials

Heat sinks can be made from various materials, including aluminum, copper, and graphite. The choice of material will depend on thermal conductivity, cost, and availability.

Fin Type

The type of fin used in the heat sink design can significantly impact its thermal performance. Straight fins, pin fins, and folded fins are some of the common types of fins used in heat sinks.

Attachment method

The attachment method for a heat sink should ensure that it is securely attached to the device it is cooling. This can vary; for instance, in the case of electronics soldering heat sinks, they may be attached through soldering for a more secure connection.

Other Considerations While Choosing Heat Sink

When choosing a heat sink, it’s important to consider its compatibility with other components in the system. This includes the size and shape of the heat sink, as well as its thermal performance and power requirements.

Additionally, you’ll want to consider the ease of installation and maintenance, as well as the quality and reputation of the manufacturer. Speaking of manufacturer reputation, one brand that stands out in the thermal management industry is Kingka. They have a strong reputation for producing high-quality heat sinks and other components for efficient thermal management.

Conclusion

In conclusion, choosing the right heat sink for your system involves considering various factors. Compatibility with other components, ease of installation and maintenance, and the quality and reputation of the manufacturer are all important considerations.

By taking the time to carefully choose the right heat sink, you can ensure optimal performance and reliability for your system.