Bullet teeth can be customized to meet specific drilling needs. Customization options include:

- Material: Bullet teeth can be made from different materials, such as tungsten carbide, steel, or diamond, depending on the type of drilling application and the hardness of the material being drilled.

- Shape: Bullet teeth can be designed in different shapes to improve drilling efficiency, reduce wear and tear, and optimize penetration. For example, some bullet teeth have a conical shape that makes them more effective in penetrating hard rock formations, while others have a flat shape that provides better stability and cutting power in softer ground.

- Size: Bullet teeth can be customized in different sizes to fit various auger bit diameters and drilling requirements. Larger teeth can be used for more heavy-duty drilling, while smaller teeth can provide more precision and accuracy in tighter spaces.

- Coatings: Some bullet teeth can be coated with specialized materials, such as tungsten carbide or diamond, to enhance their durability, wear resistance, and overall performance.

Customizing bullet teeth can improve drilling efficiency, reduce wear and tear on the auger bit, and optimize drilling performance in various soil and rock formations.

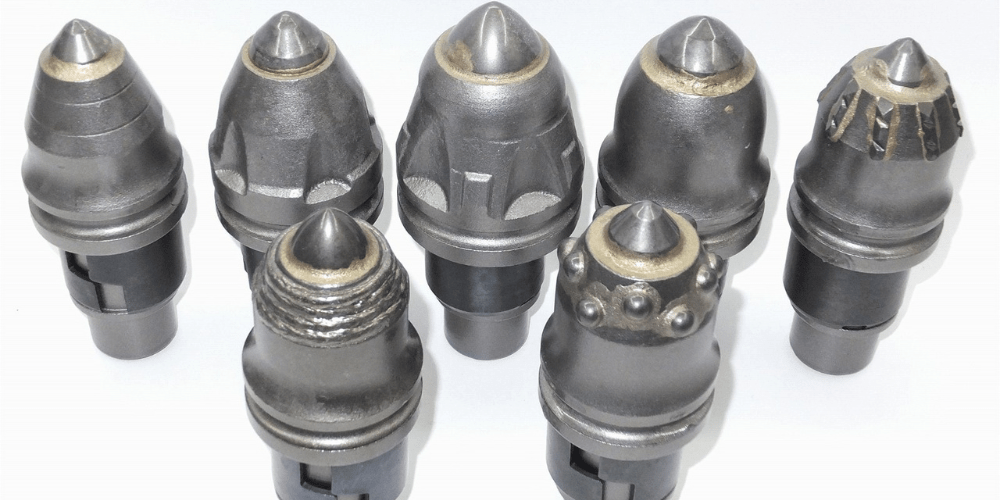

Different shapes of bullet teeth:

Bullet teeth come in different shapes, each designed to optimize drilling performance in specific soil and rock formations. Here are some of the most common shapes:

Conical:

Conical bullet teeth have a pointed tip that makes them effective in penetrating hard and compacted soils, as well as rock formations. They are commonly used in foundation drilling, mining, and road construction.

Flat:

Flat bullet teeth have a flat, rectangular shape that provides better stability and cutting power in soft and loose soils, such as sand or clay. They are commonly used in drilling applications that require precision and accuracy, such as environmental drilling and geotechnical drilling.

Chisel:

Chisel bullet teeth have a flat tip with two angled edges that resemble a chisel. They are commonly used in drilling applications that require a balance of cutting power and penetration, such as drilling in hard soils and rock formations.

Button:

Button bullet teeth have a round shape with a flat tip and are commonly used in hard rock drilling. They are designed to provide maximum penetration and durability in tough drilling conditions.

Auger:

Auger bullet teeth have a curved shape that resembles the blade of an auger. They are commonly used in drilling applications that require cutting through frozen or compacted soils, as well as drilling in hard rock formations.

The choice of bullet teeth shape depends on the type of soil or rock formation being drilled and the drilling conditions. By selecting the right shape of bullet teeth, drilling efficiency and performance can be optimized.

What is the best shape of bullet teeth and why?

It is important to select the appropriate shape of bullet teeth based on the specific drilling requirements and conditions. The expertise of a drilling professional or the guidance of the auger bit and bullet teeth manufacturer can help determine the most appropriate bullet teeth shape for a particular application.

For example, conical bullet teeth are effective in penetrating hard and compacted soils, but may not be as efficient in softer soils. Flat bullet teeth provide better stability and cutting power in soft soils, but may not be as effective in hard rock formations. Chisel bullet teeth provide a balance of cutting power and penetration, but may not be the best option in very hard or abrasive rock formations.